What makes a knife....a knife?

It's been a while since I wrote anything. Basically I did not feel "triggered" for a while as well as being rather busy with other things in my life. But recently something triggered some thoughts of mine and I thought I'd do another writeup.The War Wizard and his edict.

As an early 20 something I really got into the writings of Terry Goodkind. Somehow his books really spoke to me. What helped was the fact that the main character was a wizard/swordsman who when he fought had the the following directive:"It means only one thing, and everything: cut. Once committed to fight, cut. Everything else is secondary.

Cut. That is your duty, your purpose, your hunger. There is no rule more important, no commitment that overrides that one. Cut." (source)

|

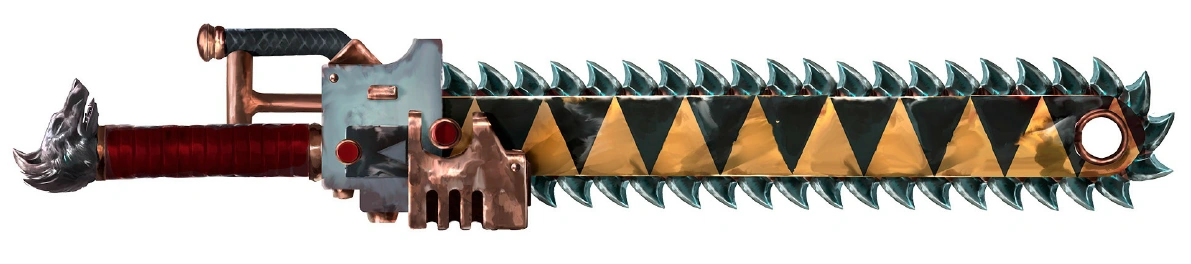

| Only way that could've been cooler would if he used a chainsword |

|

| Awesome indeed...I would probably still do it if it were lik this. |

Now that I make knives my the edict for my blades is pretty much the same. That's what they should do and in general...they do it pretty well.

But....why? And how can you recognise something that will cut and cut well?

What influences the edge?

|

| And with some knives...the design is so impractical that it really doesn't matter...... |

- Steel type

- Heat Treatment (hardness of the blade)

- Edge angle

- Stock or spine thickness (how thick the knife is at it's thickest point)

- Grind/Geometry of the blade. (What shape/thickness the blade is going from the spine or back of the knife to the edge

Today's Topic: Steel Type

When we look into fiction (books/ Comics) we always see some "Ultimate steel". Looking at the most recent Marvel films for instance they talk about Vibranium (Capt. America's Shield for instance) a lot. Apart from that metal there's mention of Adamantium (Wolverine's Metal Claws and infused skeleton). Then in the movie Avatar they talk about "Unobtanium". And in decades past Titanium was seen as the Unobtanium (different link than the last one) that everyone wanted. So much in fact that right now there's still a bit of a Titanium craze going on.

But fictional or hyped metals aside....what makes a metal suitable to make a knife out of. And for that...we have to go down to Chemistry. And what the difference in between Iron (an element) and Steel (An alloy).

We all know about Iron. Iron is the stuff that we see all around us. The stuff that rusts when it gets wet. The stuff they make ships out of.

Or is it? See it turns out..that Iron on itself is pretty soft and rusts easy. So for a lot of purposes it's not that good after all.

But we CAN make it better at certain things. This is when we start making alloys. The romans and those before them had already discovered that certain metals like Copper were pretty good...but if you mixed them in with other metals you could make things like Bronze. Which has some other desireable properties.

|

| In the air? Yup....in steel? Well I wouldn't want my blade to smell like a fart....but I'm pretty happy with carbon being where it is. |

The same can be done with Iron. For instance you can add some Carbon to the mix (yes, carbon, the stuff that we all worry about in emissions is a very usefull additive to iron). And when you start doing that you create what we know as "Steel".

Steel is a lot stronger than iron. Meaning it'll resist deformation (It won't bend as easily).

For steel to be usefull as a knife steel (because we use steel for lots of other purposes too, like ships, pots, pans etc) it needs around 0.6% of carbon in the mix.

As a general rule (but not a golden one, this is a bit of a simplification but a useful one) the more carbon you add to a steel the harder you can make it with the heat treat. (We'll talk about that in the next blog)

|

| No...no that kind of Chrome. |

Then there are other ingredients you can add to the steel. One of the most important ones is Chrome. Which is used to make a regular steel resist corrosion (Rust) better. The more chrome in the mix, the less likely the steel is to rust.

|

| Who knew you could burn a knife too? |

Then there are things like Vanadium and Tungsten which can make for very small...very HARD pieces in the steel. (Carbides) Offcourse the harder something is, the less likely it'll be to wear down (get dull) so lots of small extremely hard bits in a metal could mean that the knife made from it stays sharp longer.

There are quite a few other things than can be thrown into the mix. But what it comes down to is, like with a cake...where the ingredients will for a large part determine what the end result tastes like.....the ingredients in the steel determine for a large part how the knife will behave when finished.

Like with a cake though....if you build it wrong, or overheat it, or underheat it you can still easily ruin it no matter how nice the original ingredients were.

What can we conclude?

A little bit more about steel. And offcourse why knife collectors rave about it sometimes. In general the more expensive the steel is. The better it'll be at certain things. A steel with a lot of ingredients might stay sharp for a very long time. But you might not be able to GET it as sharp because at a microscopic level there are bigger particles in the mix. (The smaller something is...the better it'll cut things,)

This is why for a long time a lot of people thought Stainless steels were no good for knives. Stainless steels have more ingredients and therefore a courser grain (bigger pieces), bigger pieces cut less efficiently. But most carbon steels have relatively few ingredients and therefore smaller grain /particles so they cut better.

Technology has since caught up quite a bit and we can make steel do all sorts of funky stuff....like, have a steel that doesn't rust and has hardly any cabon in it or stainless steel that has as fine a grain as most cabon steels or steel that can be hardened so much than almost nothing but diamonds will sharpen it.

|

| The picture has to be compl |

But when it comes down to it. Even the cheap steels will "make a decent cake" if the proper recipy is followed.

Will a more expensive steel make a better knife? Sure...if all the other factors are also done right. But if not....tough cookies. Your expensive $500 knife with unobtanium steel might just be outcut by the simple and humble Opinel that can be bought at your local hardware store for $15. (Not affiliated with Opinel....just owned one as a boy (still do) and they're great knives).

Next installment: Hardening and basics about Heat Treatment

Ofcourse this blog wouldn't be complete without some bonus knife pictures of the stuff I make.

Geen opmerkingen:

Een reactie posten