|

| CONAN, not Cohen...oh well. |

Treating something hot

It's not exactly like what you picture

We've all seen scenes in Conan the Barbarian, The Hunted and many other films where they take ared hot blade and stick it in a bucket of icewater, or a bank of snow or something along those lines.

We've heard (horror) stories about persians who quenched their blades in the bellies of slaves to make them better and the magical properties of moonlit forging.

As you know however Hollywood has a tendency of hearing something....and then completely screwing it up in their films. So that, while the basis of what they're showing is true, they're completely missing a LOT of important details.

|

| Because four hands on a keyboard are WAY faster than two everyone knows this! |

Recap, steel

So a brief recap, steel is iron mixed in with carbon and often some other elements like chromium to give it the desired properties.The main interesting one is Carbon though. And whether it contains carbon or not determines whether the metal/steel can be hardened.

|

| Iron balls? |

stress. Granted, iron is still better than a lot of other materials, copper for instance is softer still. But when using a knife it's kind of nice to not have to sharpen it again everytime you make the initial new slice in a tomato. Or when cleaning a carcass when hunting you have to sit down and resharpen it after making the first cut.

Offcourse you could just use a harder material like stone...but that comes with a whole host of other problems. Because since it's so hard when having it in thin slices (like on the cutting edge of a knife) it becomes brittle. So a knife needs a combination of hardness (so it stays sharp) and flexibility (so that chunks don't break out of it while using). It's like a balancing act.

And so far, the best material at this balancing act is hardened steel.

Heat treatment, how does it work?

|

| Sooooo metal! |

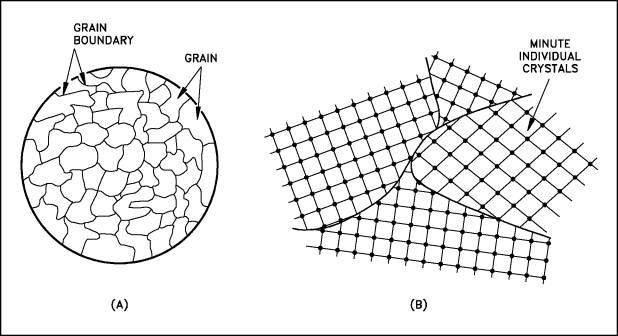

Iron atoms have a crystal type structure. In other words, a very organised structure. The comparison doesn't work 100%, but picture honeycombs. You know the hexagonal shape that they have and how it's repeated all throughout the beehive. Iron is like that when it's cold.

It's like a 3d honeycomb structure. Like a rubber ball with hexagonal sides all around.

|

| Bounce bounce bounce |

If you've ever handled one of these then you know you can squeeze and manipulate the shape of it all over the place.

Now steel however it like lots and lots of these all stuck together. With harder pieces in between the balls. Just for picture's sake let's say there's little black balls stuck in between the red rubber balls that are exactly big enough to be on the inside of the red balls.

What we WANT is to get the black balls inside of the red structures. This will make the steel harder (because of the black balls on the inside the red balls won't be able to compress anymore) but still somewhat flexible (the red balls can still stretch).

Now the black balls are bigger than the hex openings in the red balls....so something needs to happen to make those bigger.

To make the openings bigger we're going to heat up the material. When materials get hot the atoms and molecules start moving around more. When they move around more they require more space. So we heat up the material past a certain point and the red balls get slightly bigger, just big enough to let the black balls into the structure of them.

Now if we let them cool down slowly, the red balls will squeeze out the black balls again. And essentially nothing will have changed.

However if we go FAST and cool the material fast enough then (somehow) the red balls get smaller so fast that the black balls don't have the time to move out of them. And we have hardened steel.

That's the first step, we call this "Quenching" the steel.

You can imagine that something that happens so quick...might not be the most stable of structures. In fact, most of the time. This structure is so hard that it's become brittle. Now remember, brittleness is something we've wanted to avoid all along. Otherwise we'd have been better off with something like glass or stone.

|

| The only acceptable brittle |

For example, if you take a really hard metal like a file (steel files are extremely hard, they have to be because they have to CUT other steel) and throw it on the stone tiles, it'll break into two or three pieces.

Take that same file, temper it a bit more and do something similar and it'll end up scratched, but still in one piece.

Heat treatment practises

So how does this go in practise? Well. You heat up the steel to the appropriate temperature (anywhere from 820° celcius up to 1200° celcius) and keep it there for the appropriate time. Remember, for perfection you have to give the red balls enough time to absorb the black balls. For some steels (simpler steels with less carbon and little/no other elements) this goes almost instantaniously when it hits the right temperature. Other steels need to be kept at a certain temperature for a certain time to ensure the transformation of the whole steel. |

| For bonuspoints....do this kind of stuff WITHOUT the gloves... |

Some steels require a FAST cooling like water or salt saturated water.

Other steels work best with oils.

Other again work best through cooling them with cold metal plates (aluminium or steel) and others again just need to cool down in "normal" temperatur air.

All of this depends on how hard you want the steel to be, the kind of structures you want the steel to have and what ingredients are in the steel.

After hardening tempering can correct the hardness and the grain structures that you didn't want. Tempering is done on much lower temperatures than quenching temps. More between 180° celcius and 300° than the extreem red hot temps.

Hardness and grain structure

The eventual goal offcourse of all this hard work is to get the steel hard enough and flexible enough. Hardness can be seen/measured by hardness testing. In working with steel we generally work with the Rockwell C scale. It measures hardness by clamping the steel in something. And then pressing a tiny diamond or other hard point into the steel with the same force every time. Depending on how deep the dent goes you can see how hard something is.In general, the harder a steel is. The longer it will stay sharp when using.

|

| Yes....smiths are nerds and they LOVE diagrams and charts and graphs |

While we all agree about one thing, "finer grain is better". We don't really have an ideal hardness.

That one depends on all sorts of stuff, intended use, type of steel, type of knife, thickness of the grind and all factors like it.

For a big wood chopping knife you don't generally want it to be too hard. It might break, or pieces might snap off.

On the other hand on a pocket knife, that's only used for softer materials (meat/vegetables/fruit etc) maybe you'd want as hard as possible since there's very little risk in it breaking.

A lot of thought goes into the end result And if done wrong the results can be pretty bad....if done right the results can be amazing.